When to Replace Top Entry Filter Bags

The main indication that you should replace your filter bag is increased pressure differential. Filter bags become clogged throughout use, making it more difficult for liquid to pass through the system. It is important to monitor the pressure drop across your filter housing.

How Long Do Filter Bags Last?

- While this is a commonly asked question, there is no straightforward answer to how long your filter bag will last. Influences such as system requirements, materials and liquids filtered, degree of filtration and dirt load, will all impact your filter bag’s lifespan.

When to Replace Top Entry Filter Bags

- Using Filter bags and bag filter systems are a convenient way to remove contaminants or particulates from liquids during many applications. However, to function as designed, filter bags must be replaced to continue performing at properly. Filter bags that are not properly maintained may potentially result in waste or unwanted product getting through, slowing production efficiency and creating rework.

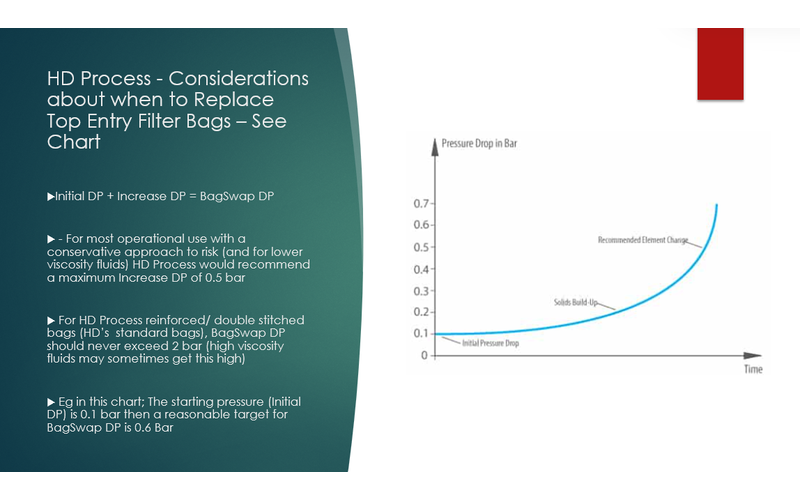

- The pressure drop across a clean filter system (Initial DP) will be affected by such factors as the size of the filter, product flowrate, product viscosity, micron rating of the (clean) bag. Once a bag starts to block with retained product the open surface area of the bag reduces and the pressure drop across the filter increases (to BagSwap DP). The difference between these 2 values we call Increase DP.

- EQUATION - Initial DP + Increase DP = BagSwap DP

- For most operational use (for lower viscosity fluids) HD Process would recommend a maximum Increase DP of 0.5 bar

- For HD Process reinforced/ double stitched bags (our standard bags), BagSwap DP should never exceed 2 bar (eg high viscosity fluids may sometimes get this high - above this DP value there is a risk of a tear or break in the bag)

- Ie; If the starting pressure (Initial DP) is 0.3 bar then a reasonable target for BagSwap DP is 0.8 Bar in a low viscosity application

- Users should consider also risks as the result of contamination;

- - For a conservative approach then use a lower figure, however for a process that is less critical from a contamination perspective then a less conservative DP could be considered.