CIP (Clean in Place) and SIP (Steam in Place) Automatic Systems

HD Process supply Automatic CIP (Clean in Place) and SIP (Steam in Place) systems. Automatic clean in place – CIP and SIP systems are used in beverage, dairy, juice, beer, sugar, biological, pharmaceutical industries to ensure sanitary conditions for production by arranging predetermined recipes to thoroughly, achieving disinfection sterilization, and guarantee sanitary conditions.

Generally these systems are designed as 3 tank system (water, alkali and acid) with available tank sizes available from 100 L to 4000 L.

All tanks are able to be individually filled and heated to a predetermined setpoint. Heating is generally carried out with a plate and frame heat exchanger, however coil, tube heat exchanger, and direct electric heating are also available.

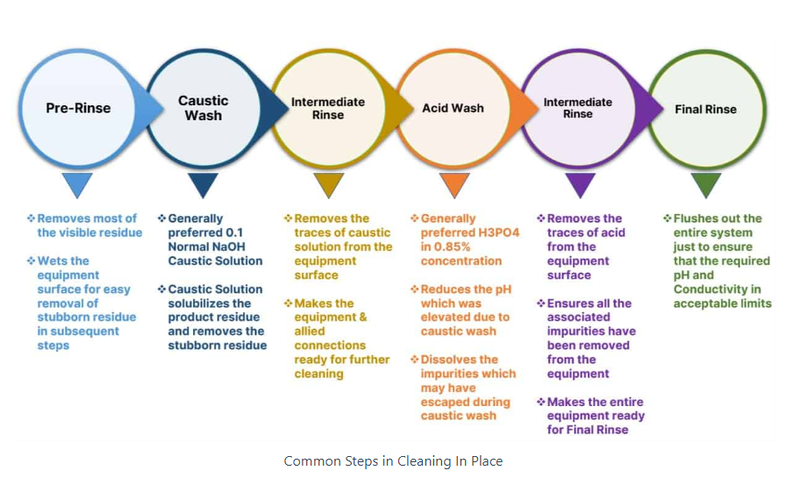

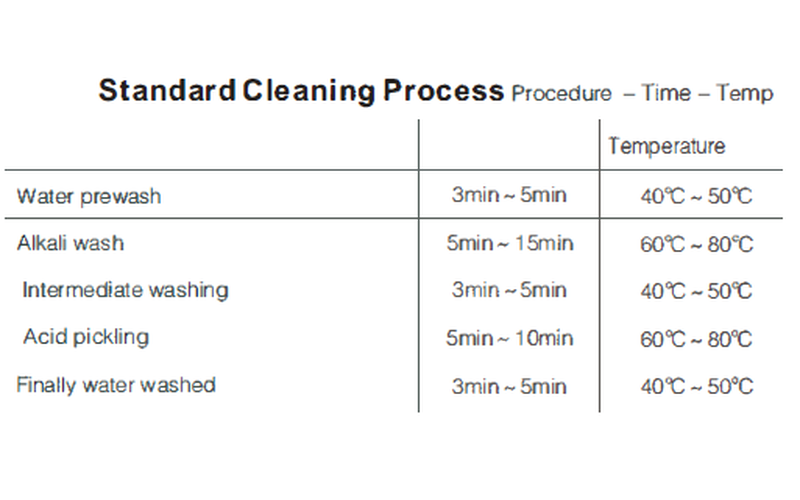

See example CIP recipe ( in this case 18-40 minutes with 3-5 minute cycles). Eg order of process - alkali wash, intermediate washing, acid pickling and final water wash

Pumps have 2.2 kW for small systems and range up to 7.5 kW for some larger ones. Target pump heads are 2 bar and greater. Flow rate is largely dependent on pipe diameter. Ideally flow should be achieving around 2 m/s through pipe systems. Sprayball's are sized and positioned for optimal cleaning effect.

Standard system spec includes;

- 3 x cleaning fluid storage tanks along with piping and distribution.

- PLC with touch screen interface and multiple recipes

- Booster pump, recirculation pumps, acid-base metering pump

- Plate heat exchanger with temperature controller

- Instrumentation includes, electrical conductivity sensors, temperature sensors and liquid level sensors

- Pneumatic control valves