SMART PUMPS and BATCH CONTROLLERS

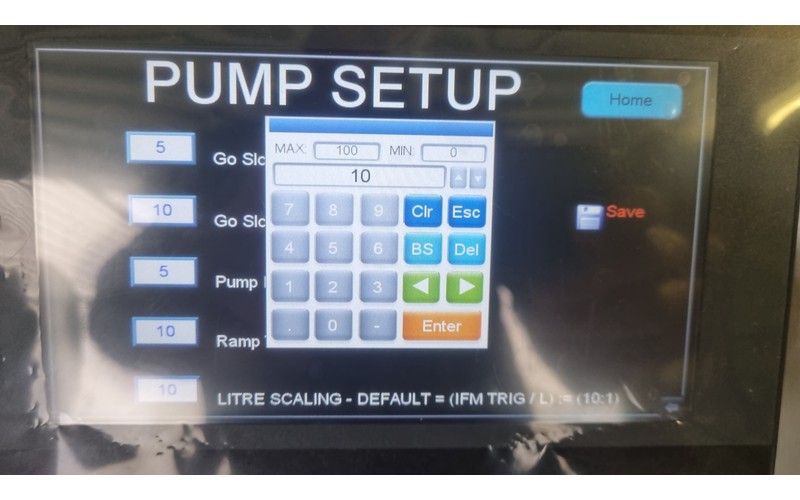

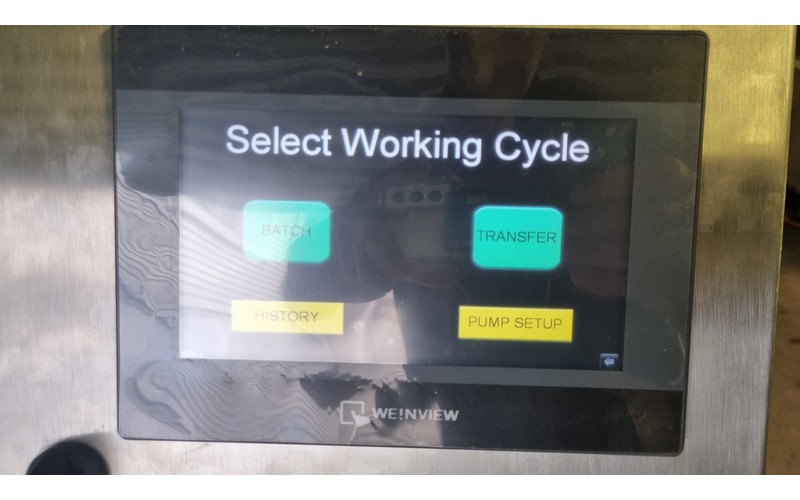

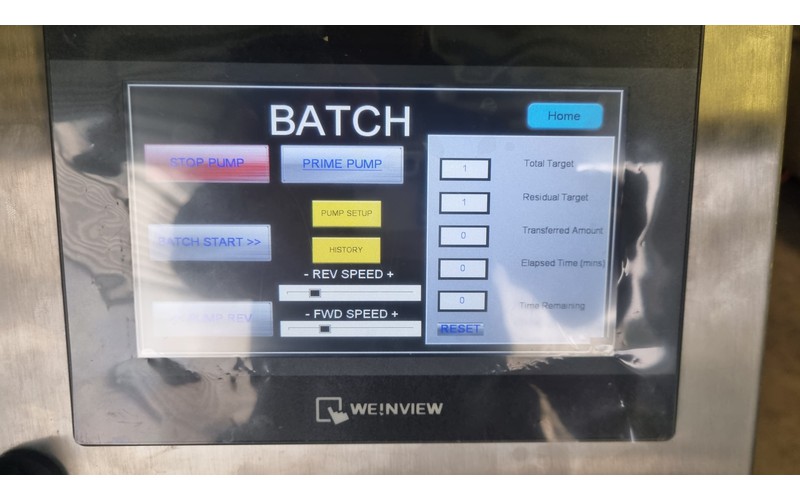

HD Process provide SMART pumps (pumps controlled by PLC and HMI/ programmable logic controllers and human machine interface) for easy operator use and greater flexibility in control. HD Process pumps are also configured to operate through more standard BATCH CONTROLLER interfaces (preconfigured dedicated controllers for batch dispensing).

These products are designed to allow the operator to either deliver an accurate measure for a dose/ filling application (bottle/container/bag/tank) or to be able to walk away and allow a larger predefined batch volume to be delivered tank to tank.

These units commonly have flowmeters mounted on board to meter volumes, however some of the more positive pumps (progressive cavity, peristaltic, lobe pumps ) are set up to operate with encoders or pulsing proximity sensors feeding back to the controller interface (providing control without their use of a flowmeter).

Flowmeters that are used include magnetic flowmeters (for conductive/water-based products ) and specialist positive displacement flowmeters for oils.

Some of the pumps that HD process can deliver with controller interfaces include;

- Centrifugal pumps.

- Flexible impeller pumps

- Peristaltic pumps

- Lobe pumps

- Rubber Lobed pumps

- Progressive cavity pumps