Wedge wire screen filters SETUP

HD process supply wedgewire screens in several of their filters including their range of self-cleaning filters and their right angle (601 filters and GS and other ranges) and Ystrainer filters.

The wedge-shaped wires are precisely positioned and welded at each intersection to a series of support rods which create a hollow cylinder. This assembly process creates a sturdy and non-clogging screen with uniform slots, which is crucial for effective filtration.

Compared to some other options for filtration including perforated plate and mesh filtration systems, a wedgewire filter tends to be more resistant pressure spikes in the flow and differential pressures across the filter from waste build up during processing.

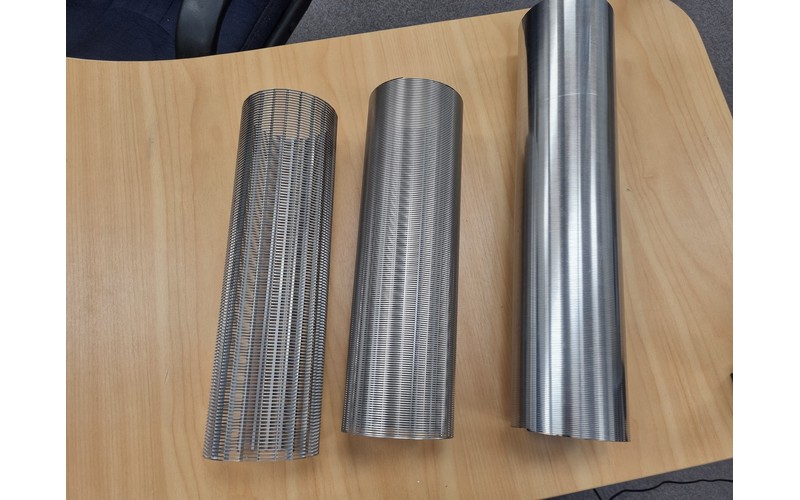

In many cases this filters and designed as a hollow cylinder.

The cylinder either retains solids by flow ‘IN TO OUT’ (solids retained on the INSIDE and filtered product leaves the filter from the outer shell of the cylinder)

or ‘OUT TO IN’ (solids retained on the OUTSIDE and filtered product leaves the filter from a port in the bottom of the cylinder.)

Photos are attached here of a variety of cylinders – note that in these cases there is a rectangular slot in the wedgewire with vertical bars delineating long side of this rectangle (in the case of one of the units in the photo this creates a 15 mm long slot, with a 2 mm gap).

The wedgewire itself has thicker and narrower ends to it. The thicker side is always presented in the direction of flow (in order to create a restriction for solids - however once the solids have passed this point the wedge widens and solids tend to easily pass through