Plunger Filters (Bernoulli Effect)

HD Process plunger filters provide continuous filtration on pressurised water systems. Ideal for sea water, river water and circulating cooling water, the design uses the Bernoulli principle: a moving plunger creates a local low-pressure zone that lifts debris off the wedge wire screen for non-contact cleaning. Purging can be triggered by a PLC timer or by a differential pressure sensor.

Why choose a Bernoulli filter?

- Continuous filtration, no downtime: Back-flush cleaning occurs while flow continues, protecting downstream equipment and heat exchangers.

- Gentle, non-contact cleaning: A Bernoulli cleaning disc creates a local low-pressure zone that back-flushes the screen surface—no brushes, minimal wear, higher capture efficiency.

- Low inlet pressure requirement: Operates from low system pressures; ideal for low-head intakes.

- Wide operating envelope: Typical filtration ratings 150–2000 µm and single-filter flows spanning tens to thousands of m³/h.

- Smart, automatic control: Differential pressure (DP) and/or timer-based cleaning.

- Compact, easy to service: Motor-driven, single-basket design simplifies maintenance and saves install space.

Key Features

-

Simple, reliable mechanism with only two moving parts, the cleaning disc and the flushing valve.

-

Non-contact cleaning, no particle extrusion through the screen, longer media life.

-

Low, consistent pressure drop ≤ 11 kPa in clean and dirty conditions.

-

Operates at low line pressure, ≥ 30 kPa.

-

Wide single-filter flow range, 30 to 8,000 m³/h.

-

Filtration degrees from 150 to 2,000 µm.

-

Self-cleaning without interrupting filtration maintains a steady flow.

-

Install horizontally or vertically to suit piping layout.

-

Automated purge via PLC time program or ΔP setpoint for water savings and predictable maintenance.

How it works

-

When cleaning starts, a motor drives the disc toward the basket screen. Water accelerates through the small gap between disc and screen, lowering static pressure around the disc edge (Bernoulli effect). That local vacuum draws already-filtered water back through the screen, lifting particles off the surface and sending them out via the flushing valve—without rubbing the screen

Ideal applications

- Cooling water loops and heat-exchanger protection in industrial plants

- UV and UF pre-filtration, spray nozzle protection, ballast water pre-treatment

- Raw water intakes (river, lake, sea), process water and waste-water pre-filtering

Cleaning control: Timer vs DP (which should you use?)

DP (differential pressure) mode triggers a clean when the pressure drop across the screen exceeds a setpoint (commonly ~10–20 kPa). It adapts to changing solids loads, minimises unnecessary purges, and typically saves water and energy.

Timer mode cleans at fixed intervals (e.g., every 5–20 minutes) regardless of fouling. It’s simple, good for steady and predictable loads, or as a safeguard where DP instruments aren’t used.

Best practice: run DP OR timer—whichever comes first—to guarantee cleaning if either fouling rises quickly (DP trips) or the DP sensor drifts (timer back-stops it). Include a minimum interval between cleans to prevent short-cycling, and log DP before/after each purge to confirm screen health over time.

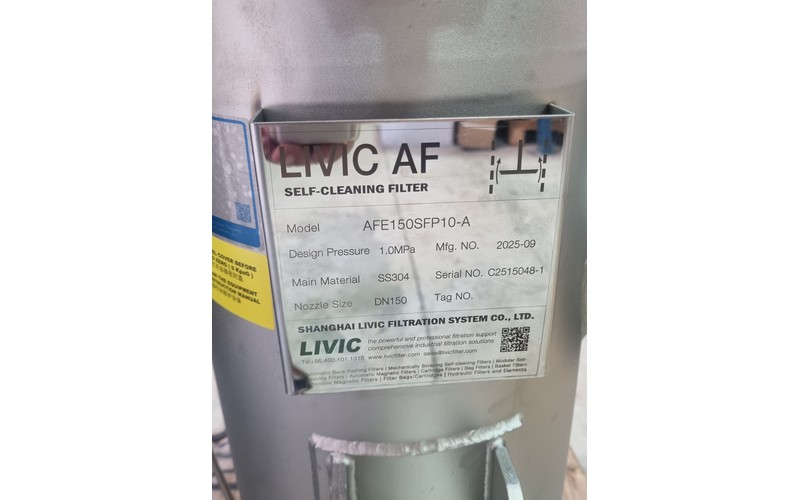

Ask us to size a unit for your water quality, target cut-point and design flow. You can also refer to the downloadable brochure to review the AF range.