Liquid Ring Pumps NZ – A, AS, CNH Self‑Priming Pumps | HD Process

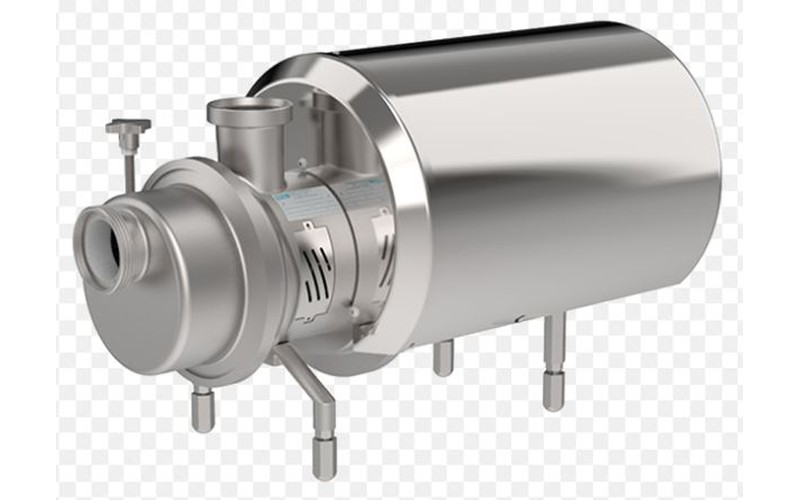

HD Process supplies CSF liquid ring pumps engineered for rapid self‑priming and dependable suction when air or gas is present. The A and AS series feature star‑shaped impellers and independent shaft support; the AS range is fully hygienic while the A series suits less demanding sanitary plants. The CNH series combines a helical rotor and open impeller to deliver a self‑priming centrifugal pump in compact dimensions. All wetted parts are investment‑cast in AISI 316L stainless steel, with electro‑polished finishes for easy cleaning.

Designed to maintain vacuum and prevent cavitation, these pumps excel in CIP return, foaming liquid handling and tank scavenging duties across food, beverage, dairy, pharmaceutical and chemical processes. They offer a wide choice of mechanical seals, FDA‑certified elastomers and international connection standards to match your installation. Quick disassembly and adjustable feet make maintenance straightforward, reducing downtime.

Key specifications

- Construction: investment‑cast AISI 316L (1.4404) / CF3M (1.4409) stainless steel with electro‑polished surfaces

- Self‑priming capability via star‑shaped impeller (A/AS) or helical rotor device (CNH)

- Flow range: 0.5 m³/h to over 60 m³/h; head up to ≈55 m depending on model

- Vacuum maintained under varying suction; ideal for liquids containing air or foam

- Mechanical seals to EN 12756 / ISO 3069 with single, flushed or double configurations

- FDA‑approved elastomers: EPDM, Viton, silicone and PTFE (FEP)

- Connection options: DIN, SMS, IDF, BS/RJT, DS, CLAMP and EN 1092‑1 PN16 flanges

Options

- AS series: fully hygienic, single or double stage designs for sanitary CIP return and tank emptying

- A series: industrial liquid ring pumps offering the same self‑priming performance for less stringent hygienic duties

- CNH series: compact self‑priming centrifugal pumps with open reverse‑vane impeller for air‑entrained liquids

Applications

- CIP scavenge and return of cleaning solutions

- Tank and vessel emptying, including foaming or gas‑laden products

- Transfer of water, juice, wine, spirits and chemical media

- Dairy, beverage, pharmaceutical and chemical process plants

Contact HD Process for help selecting the right liquid ring pump configuration for your application or to request technical datasheets.