Drum Pump Systems – Hygienic Drum and IBC Transfer

HD Process supply complete drum pump systems for fast, low-waste emptying of 200 L drums and IBCs. Our hygienic drum pumps are widely used in food, beverage, honey, dairy and specialty chemical plants throughout New Zealand, handling everything from thin cleaning chemicals through to very viscous syrups and honey.

Drum pumps are supplied as engineered packages, with the pump, suction lance, discharge hose, fittings and stands or plates matched to your product and site layout. Options include bung-mounted systems that keep the drum closed, or in-drum pumps that sit directly in the open drum for maximum recovery and easy clean-down.

Drum pump options

-

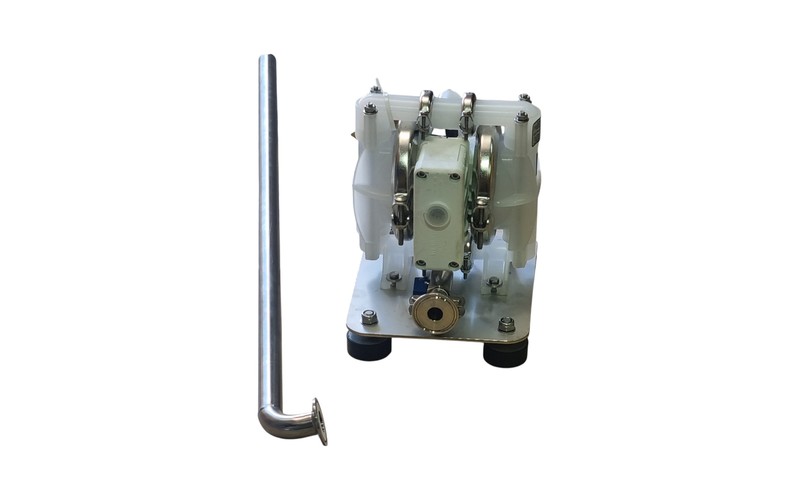

Wilden air-operated diaphragm drum pump mounted on a plate over the drum, with a suction lance down through the drum bung.

-

Pneumatic piston drum pump that sits directly in the open drum for quick decanting and transfer.

-

Electric progressive cavity drum pump with a long suction tube inside the drum for smooth, pulse-free flow on viscous products.

Key benefits

-

Fast, safe emptying of drums and IBCs with minimal product left behind.

-

Hygienic 304 or 316L stainless steel wetted parts and sanitary hose assemblies.

-

Portable or semi-permanent systems that reduce manual handling.

-

Easy integration with existing filters, heat exchangers, pasteurisers and mixing systems.

Typical applications include honey and honey blends, sugar syrups, flavours and concentrates, food oils, detergents and CIP chemicals (with appropriate elastomer and material selection).