Rotosolver - with High Shear Impeller for Dispersing, Dissolving and Emulsifying in one unit

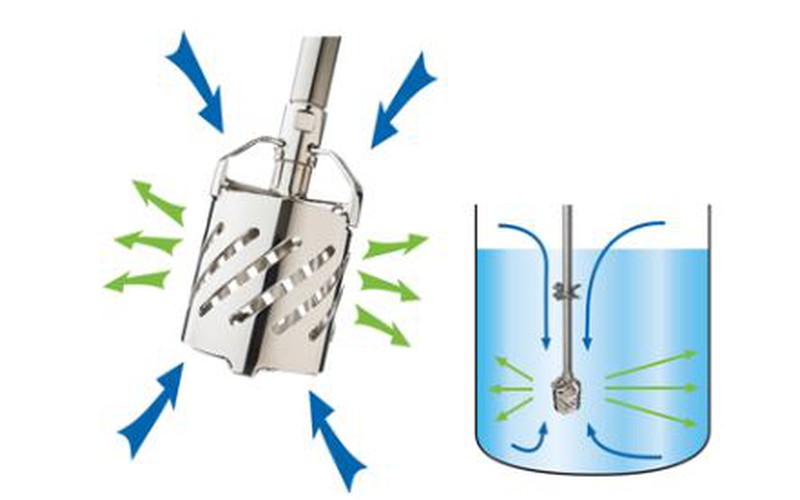

HD Process supplies the Rotosolver, a top-entry batch mixer engineered for rapid liquid-liquid and solid-liquid dispersion, fast powder wet-out and complete hydration for 100% utilisation of ingredients. Its patented mix head balances shear, particle size reduction and macro-circulation so you get uniform results from top to bottom, even in viscous batches.

Why Rotosolver

-

High-intensity shear with full-vessel circulation, shortens blend and hydration times.

-

One-piece CIP mix head, no dead zones, fast rinse-out, safer changeovers.

-

Hygienic design meets 3-A Sanitary Standard 73-01 and USDA-AMS requirements.

-

Single-shaft, obstruction-free tank entry, simplifies cleaning and maintenance.

-

All-stainless mix head, shaft, drive and motor available for aggressive chemistries.

-

Optional secondary impeller to boost turnover in tall or high-solids tanks.

-

Handles viscosities up to 50,000 cP without sacrificing top-to-bottom uniformity.

-

Fully dissolves and hydrates powders, minimises fisheyes and agglomerates.

-

No wearing parts in the product zone, reduces consumables and downtime.

-

Scalable from lab to production, with models up to 100 HP for large kettles.

Positioning vs other technologies

-

Low-speed agitators are effective for miscible liquids, but struggle with powder wet-out.

-

High-speed saw-tooth dispersers reduce particle size, yet often require long residence time.

-

Fixed rotor-stator mixers give very high shear but can limit macro-flow in viscous batches.

-

Rotosolver combines strong shear with vigorous circulation, so you achieve fine dispersion and full-tank homogeneity in one pass.

Typical uses

-

Dairy and beverage hydration, stabiliser and protein addition.

-

Sauces, dressings, condiments and flavour emulsions.

-

Nutraceutical slurries, gels and polymer solutions.

-

Personal care and specialty chemical dispersions.

Ask us to size a Rotosolver for your vessel volume, target viscosity and required batch time, and to recommend head style and impeller options for your duty.