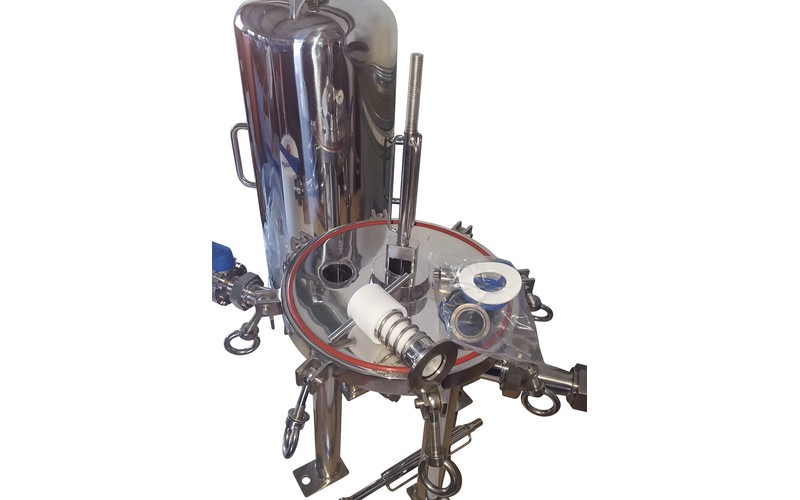

Lenticular Filter HOUSINGS

HD Process supply complete lenticular filtration systems for clarification and fine polishing of liquids in food, beverage, pharmaceutical, and chemical applications.

Key Features

- Available in 316L or 304 stainless steel to suit all process and hygiene requirements.

1-, 2- or 3-stack housings available in 12″ or 16″ diameters for a wide range of surface areas and flow rates.

Centre rods supplied in stainless steel for reduced-stack operation (e.g. single or double stack use).

Supplied complete with valving, sanitary pressure gauges, and tri-clamp connections.

Can be skid-mounted with positive displacement feed pumps and control packages for turnkey operation.

High solids-loading capability and easy change-out—ideal for polishing wines, beers, syrups, oils, honey, and pharmaceutical solutions.

Designed for CIP and SIP service, with smooth internal finishes for sanitary cleaning

Applications

-

Final filtration and polishing in wineries, breweries, honey, dairy and beverage plants.

-

Replacement for traditional sheet filters where closed-system filtration and low product loss are required.

-

Suitable for clarifying viscous fluids or products containing fine particulates.

Typical Options

-

Pre-filters (bag or cartridge) in duplex arrangement upstream of lenticular stacks.

-

Integrated PD pump skids for constant-flow operation.

-

Pressure-relief valves and drain manifolds for safety and ease of maintenance.