Liquid Powder Blender- Range

HD Process supplies liquid powder blenders, blend powders into liquids. These blenders are able to disperse solids into liquids uniformly and are an excellent choice for use in a wide variety of dairy, food and beverage powder mixing applications, such as dissolving stabilizers like pectin and xanthan gum and emulsifiers in the percentages required for most applications. Other applications include blending starches and proteins into oils and water, or adding sugar and other powders to water.

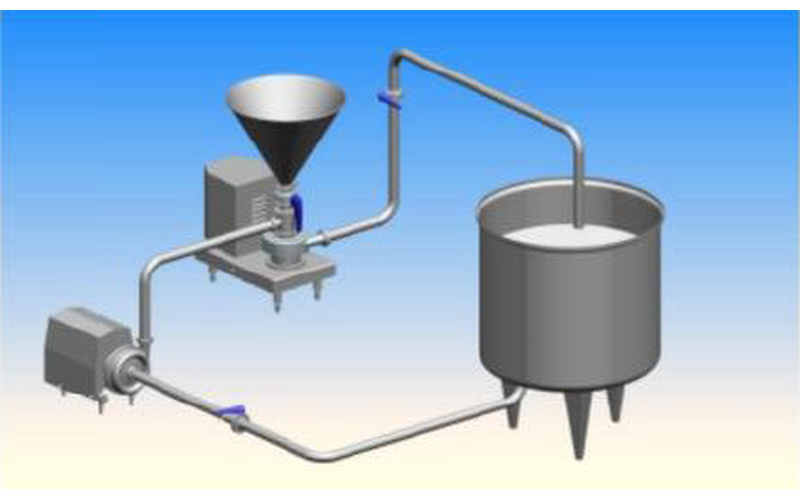

- The standard liquid powder blender comes with a relatively powerful centrifugal pump impeller (hygienic design), and a top mounted hopper. The liquid flow can be run tank to tank (single pass applications) or circulate through a single tank depending on the customer's requirements.

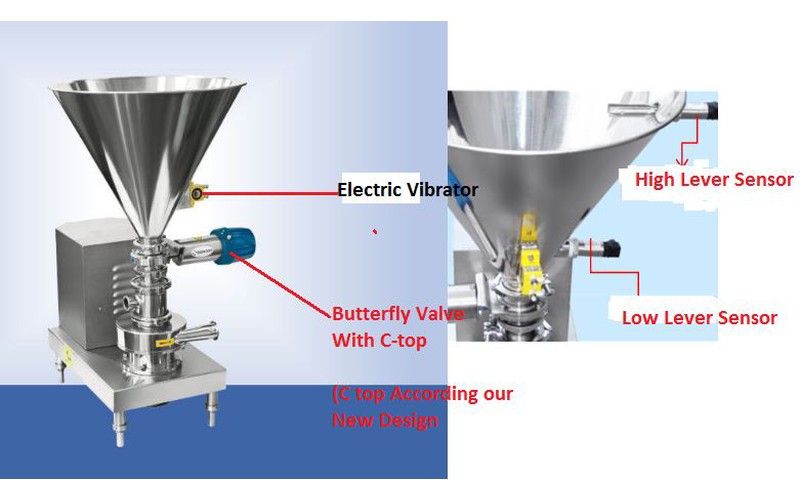

- Once liquid flow is in progress the butterfly valve separating the hopper from the pump can be opened and an orifice plate on the liquid side provides a vacuum to suck powder into the body of the pump. The centrifugal pump impeller then completely disperses/blends the powder into the liquid.

- These units can operate up to viscosities of 1000 to 2000 cP (higher viscosity is reduced flow rate and consequently reduce the suction on the powder in the hopper). See photos of how these units can be set up with options for centrifugal and positive displacement pusher pumps to maintain flowrate at these sort of viscosity levels.

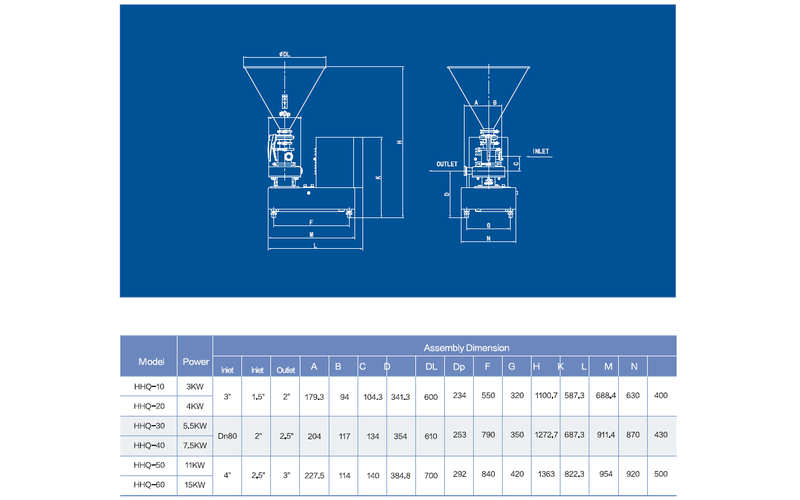

- Power supplies on these units can vary from 3 kW through to 22 Kw, with solid input rates nominally of 2 ton through to 12 tons per hour (often these input rates are more limited in real life situations). Liquid flow rates are 10,000 L per hour through to 80,000 L per hour depending on size. Hoppers come into sizes – 40 L and 70 L.