Stainless Steel IBCs –Pharma Grade Containers

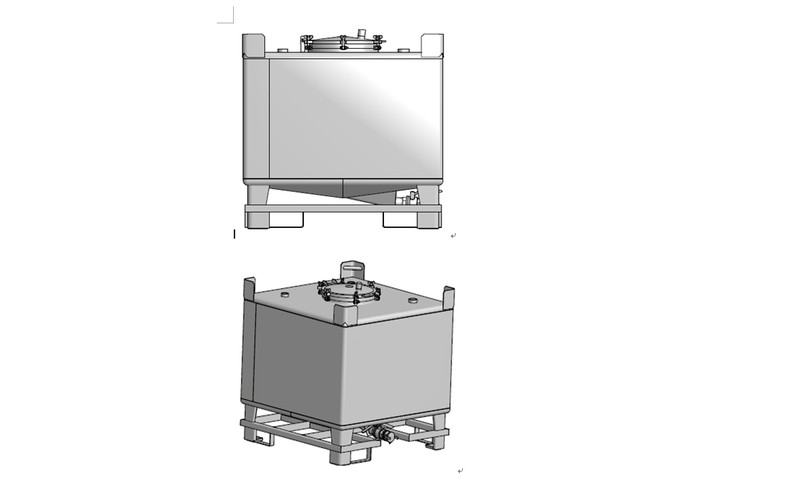

HD Process supply Hoover and CUBIC IBCs (intermediate bulk containers) manufactured in 304 and 316 stainless steel, designed specifically for food and pharmaceutical storage and transfer. These reusable containers provide a robust, hygienic alternative to plastic IBCs, with long service life and excellent cleanability.

Hygienic Construction

Each stainless steel IBC is built for sanitary duty:

-

Smooth internal surfaces with polished welds to reduce product retention

-

Food-grade valves and connections to suit hygienic process plants

-

Food-grade seals and gaskets compatible with common CIP and SIP regimes

This makes the Hoover and CUBIC IBC range suitable for high-value food ingredients, concentrates, flavours, syrups, oils and pharmaceutical products.

Valving, Safety and NZ Compatibility

HD Process supply these IBCs complete with:

-

Pressure relief valves sized for safe venting

-

Inlet and outlet valves matched to local New Zealand food-grade standards

-

Connection options to integrate with existing pumps, hoses and filling lines

This ensures the containers arrive ready to use, with fittings that match common tri-clamp and other sanitary connection systems used in NZ plants.

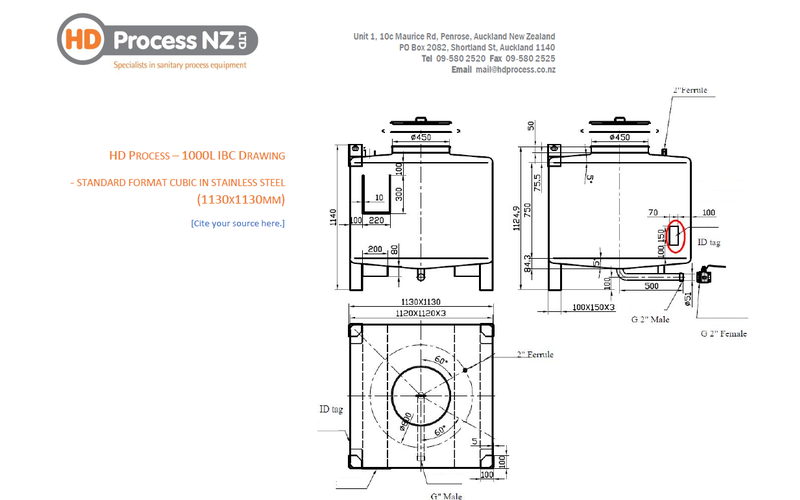

Footprint and Dimensions

Both Hoover and CUBIC IBCs are based on standard 1000 L footprints, with alternative heights available to vary working volume:

-

Hoover stainless IBC footprint

-

Approx. 1000 L standard footprint: 42" x 48" (W x D)

-

Height from floor to top of tank (excluding lugs): 41.5"

-

-

CUBIC stainless IBC footprint

-

Approx. 1000 L standard footprint: 1150 x 1150 mm (W x D)

-

Height from floor: 1140 mm

-

Using these base footprints, a range of nominal volumes can be supplied, including 500 L, 700 L, 1000 L, 1500 L and 2000 L, while still fitting standard handling and storage systems such as pallet racking, forklifts and pallet jacks.

Typical Applications

Hoover and CUBIC stainless steel IBCs are ideal where:

-

Product quality, hygiene and traceability are critical

-

Frequent filling, emptying and cleaning cycles are required

-

Long-term durability and low risk of impact damage are important

Common uses include storage and transport of food ingredients, liquid flavourings, edible oils, syrups, dairy products, nutraceuticals and pharmaceutical liquids.

Specification and Support

HD Process can assist with:

-

Selecting 304 vs 316 stainless steel based on product and environment

-

Specifying valve types, seals and connection sizes to match your process

-

Choosing the appropriate volume and footprint for new and existing sites

For detailed specifications, drawings and options on Hoover and CUBIC stainless steel IBCs, contact HD Process with your product, volume and connection requirements.

If you would like a sterile IBC Bladder/Bag for your product, please review this page: https://hdprocess.co.nz/produc...