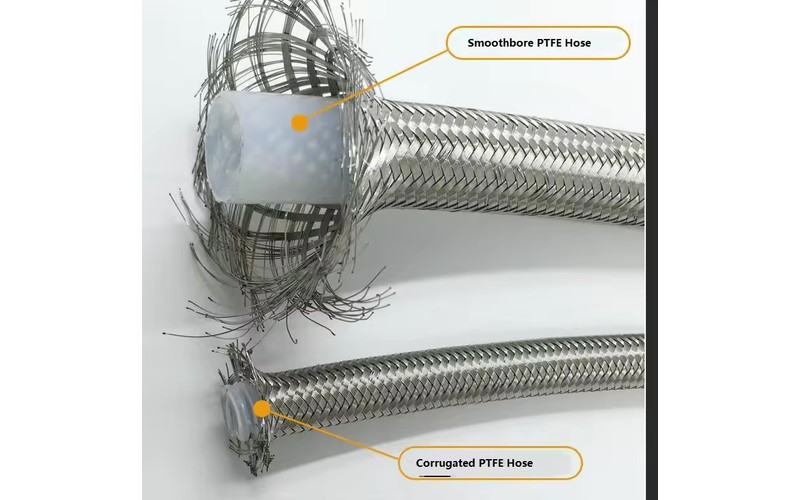

PTFE Stainless Steel Braided Hoses

HD Process supply PTFE hoses with stainless steel braid for demanding chemical, CIP and high-temperature applications in food, beverage, dairy, pharmaceutical and specialty chemical plants. These hoses combine the chemical resistance of PTFE with the mechanical strength of a braided stainless steel outer layer.

PTFE Hose Construction and Benefits

PTFE braided hoses feature a PTFE inner tube and stainless steel braided reinforcement. This combination offers:

-

Outstanding chemical resistance to many acids, alkalis, solvents and CIP chemicals

-

High temperature capability compared to many rubber or plastic hoses

-

Smooth bore options for cleanability and low product retention

-

Excellent pressure performance with a compact outer diameter

They are an ideal choice where cleanliness, compatibility and long service life are critical.

Sizes and Connection Options

PTFE braided hoses are available in multiple internal diameters to suit everything from small-bore chemical dosing lines through to larger process transfer lines.

HD Process can supply these hoses as complete assemblies with:

-

Stainless steel tri-clamp, RJT, DIN or other sanitary connections

-

Fixed or swivel ends to make installation easier

-

Custom cut lengths to suit your plant layout and routing

By matching hose size, pressure rating and end connections to your system, we help ensure safe, reliable operation.

Typical Applications for PTFE Braided Hoses

PTFE stainless steel braided hoses are commonly used for:

-

Transfer of CIP chemicals, acids and caustics in hygienic process plants

-

High-temperature product lines where rubber hoses are not suitable

-

Solvent and specialty chemical transfer in controlled environments

-

Flexible, chemically resistant links between fixed stainless steel pipework and equipment

They are often paired with HD Process pumps, valves and filters in systems that handle aggressive or high-temperature media.

PTFE Hose Selection and Technical Support

Correct selection of PTFE braided hose depends on the chemical, concentration, temperature, pressure and flow rate. HD Process can assist with:

-

Checking chemical compatibility and temperature limits

-

Selecting appropriate end fittings and seals

-

Sizing the hose for flow and pressure drop

For assistance selecting PTFE stainless steel braided hoses, contact HD Process with details of your application and required hose sizes.