Plate Heat Exchanger - Port Layout and Maintenance

Plate Heat Exchanger (PHE) Components

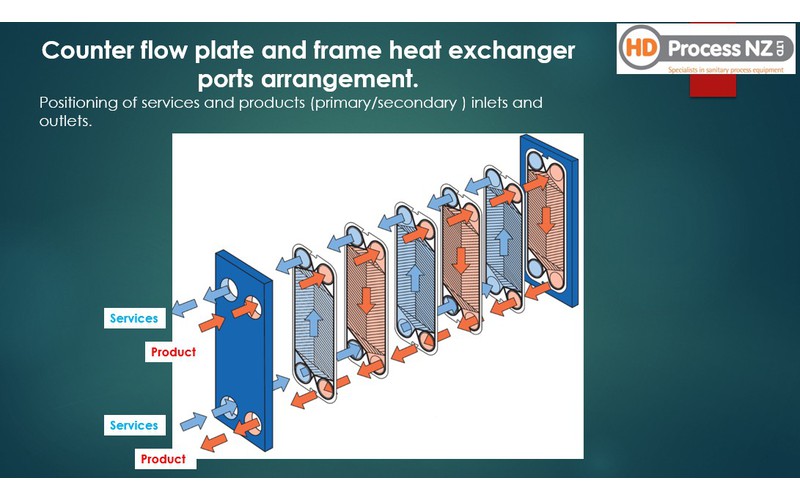

Plate heat exchangers consist of relatively few parts. Because plate heat exchangers are used for transferring heat, they require inlets and outlets where the flowing mediums -or fluids- can enter and leave the heat exchanger. A fluid may be a liquid or a gas. As fluids are often assumed to be liquid only, we will use the term flowing medium to avoid confusion.

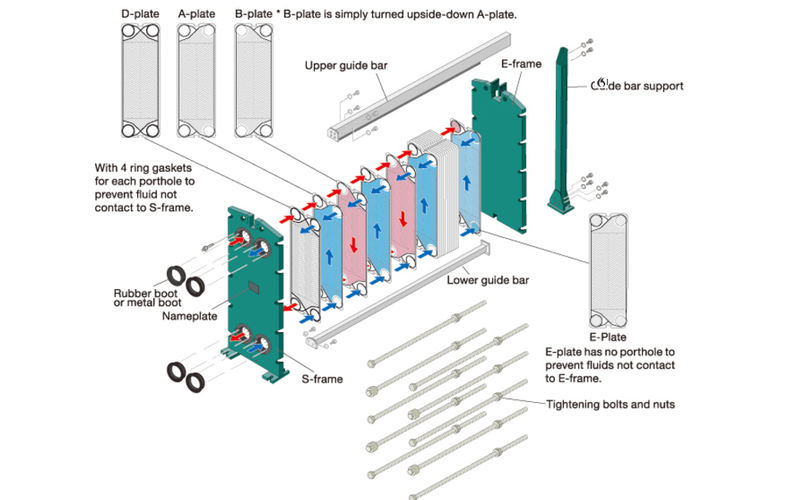

Plate Heat Exchanger (Exploded View)

Gaskets and plates are used to separate the flowing mediums and prevent them mixing; gaskets are adhered to one side of each plate only. The plates hang upon a carry bar and are pressed together using clamping bolts. When the plates are compressed together, they are referred to as a ‘plate stack’. A guide bar ensures the plates are aligned correctly when the plate stack is opened and closed

Maintenance

Before performing self-maintenance!!

One of the major advantages of plate heat exchangers is the ease of maintenance. They can be disassembled simply by removing the tightening bolts, which makes it easy for customers to replace parts and clean plates themselves.

However, performing maintenance yourself comes with the following risks.

(1) Leaving scale residue due to incomplete cleaning of heat transfer plates

(2) Overlooking pinholes caused by small corrosion and cracks

(3) Causing damage to heat transfer plates due to excessive tightening

(4) Incorrectly installing the heat transfer plates