Heating and Cooling - Refrigeration and Inductive

HD Process supply liquid heaters and chillers suitable for small and medium duties for high accuracy applications where additional temperature control is requried.

Heating and Cooling capacities from 1 kW up to 200 kW, single or twin independent gas circuits, depending on the model.

These are commonly designed to be mobile - and can be easily moved from vessel to vessel depending on processing requirements.

- Note that most of these chillers can also be run as heat pumps to provide hot services liquid.

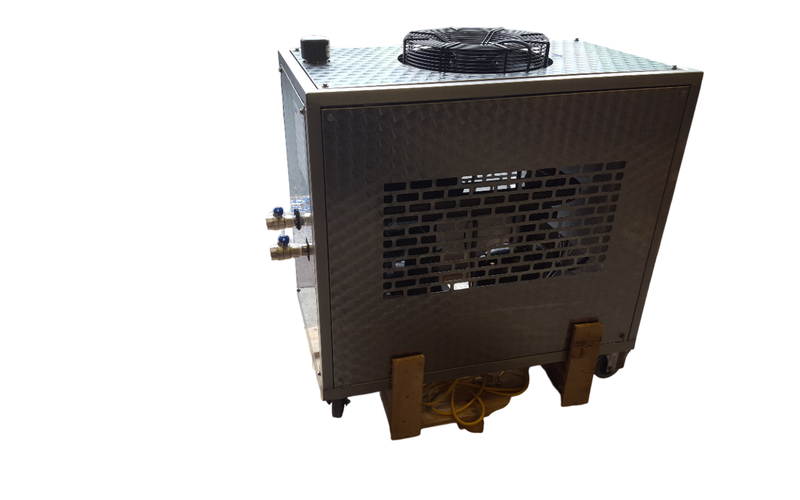

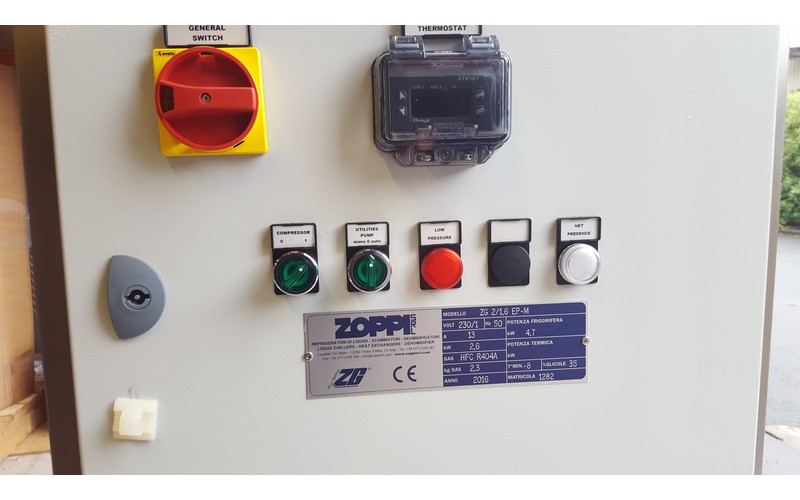

• Hermetic Scroll or semi-hermetic alternative pistons compressors

• AISI 316L plate evaporator

• Air cooled condenser with extra-large capacity

• Electrical control box for the managing of the machine, with electronic thermostat or industrial PLC

• Structure and panelling entirely made of stainless steel

• On request with heating section for the heating of the liquid

Standard working range: +45°C / -20°C

Extended working range, on request: +60°C / -40°C

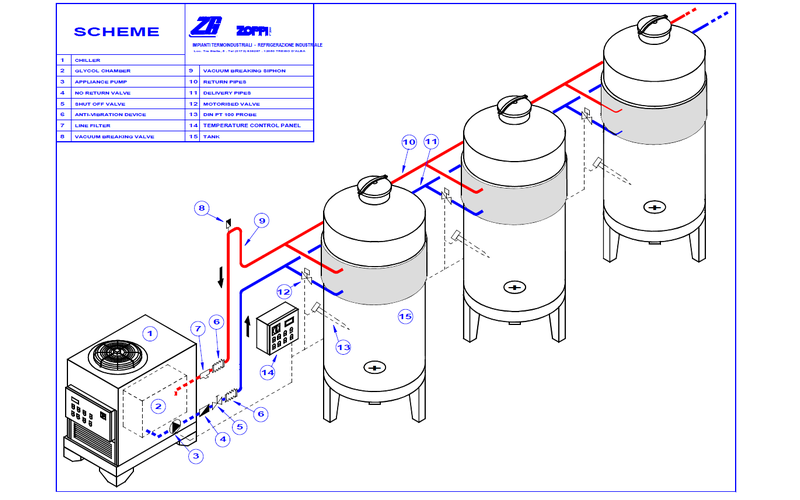

Built on monoblock structure, delivered ready to use (plug and play), are equipped, as standard, with the whole needed hydraulics, already installed aboard:

• Accumulation buffer tank, in stainless steel, insulated, with adequate capacity, for atmospheric pressure or pressurized type, for the thermal flywheel effect

• Liquid pump, in stainless steel, for the primary recirculation

• Hydraulics safety and control components: flow and level switches, pressure transmitters, etc.

• On request all pumps ca be supplied with by frequency inverters (VSDs) to keep at a defined pressure rate the head of the pumped liquid

• On request it is possible to install aboard thermoregulations for secondary sections at intermediate temperatures

Moreover, each liquid chiller can be customized to best meet the specification of utilities systems to serve.