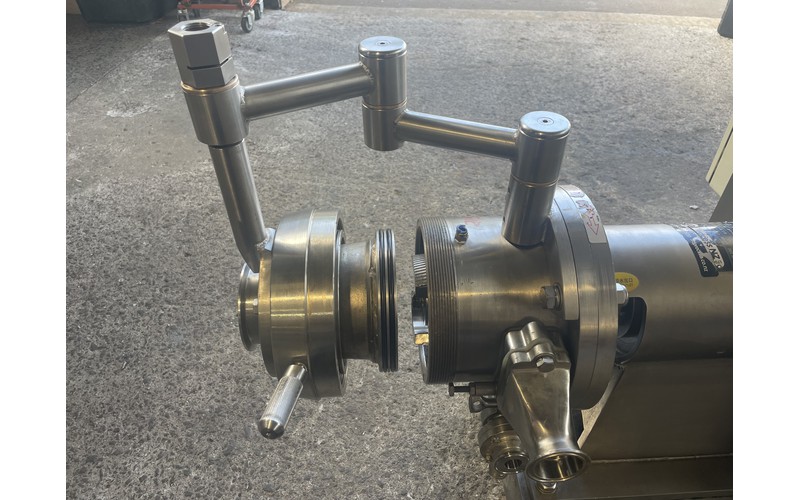

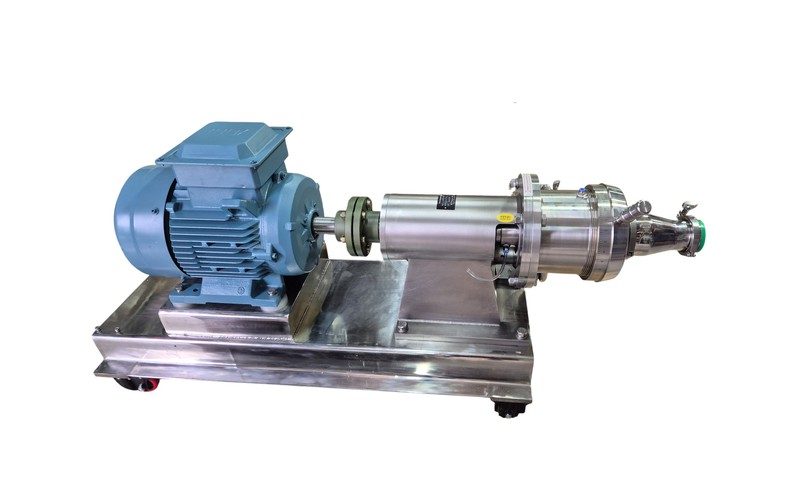

Colloid Mill - In Line version

HD Process supplies vertical and in-line colloid mills for reducing particle size in solids-in-liquid suspensions and reducing droplet size in liquid-liquid emulsions. The in-line colloid mill shown allows adjustment of the rotor-stator gap, enabling practical control of the outgoing product texture. For most applications, the mill is typically used with a pusher pump to maintain flow rate and support consistent production control.

Key specs

- Rotor-stator principle for controlled high-shear processing

- High-speed rotor operation from 2,000 to 18,000 rpm

- Adjustable rotor-stator gap (in-line model) to vary texture and finish

- Designed to improve stability of suspensions and emulsions by reducing droplet size

- Higher shear rates can produce smaller droplets down to approximately 1 µm, improving resistance to emulsion separation

- Commonly specified with a pusher pump to maintain stable feed and flow

Options

- In-line colloid mill for continuous processing and easy integration into pipework

- Vertical colloid mill for batch or semi-batch processing setups

- Pusher pump pairing for flow control and production consistency

- Process integration support - valves, fittings and instrumentation as required

Applications

- Emulsions where droplet size reduction improves stability and appearance

- Suspensions where particle size reduction improves uniformity and processing performance

- Food and beverage, chemical and general process duties where texture control is important

Share your product type, target texture, throughput and cleaning requirements, and HD Process NZ can recommend an in-line or vertical colloid mill configuration and the right pusher pump arrangement.