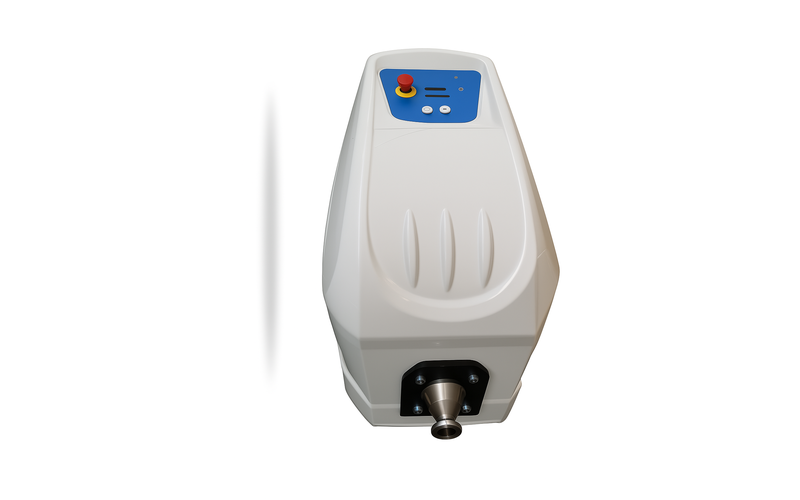

Bertoli Colloid Mills - Inline Colloid Mills

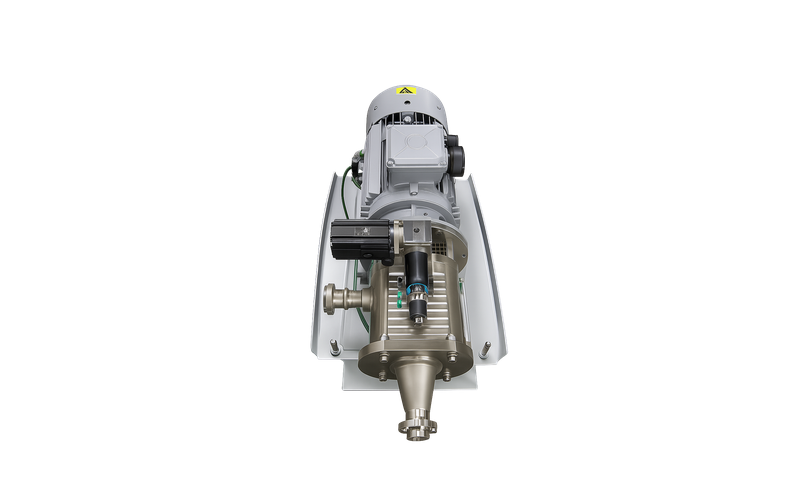

Bertoli in‑line colloid mills deliver consistent, fine grinding for liquids, emulsions and semi‑solids. Built around a high‑speed rotor/stator, they mill down particles to around 50 µm while maintaining high throughput and hygienic operation. These Italian‑made units are suited to dairy, beverage, biotech and chemical processing where controlled shear and CIP cleanability are essential.

Key specs:

-

Grinding range down to 50 µm for uniform particle size

-

Product flow rates up to 25,000 L/h

-

Max operating pressure 6 bar with installed power up to 55 kW at 3,000 RPM

-

Dual cartridge mechanical seal using tungsten carbide and EPDM for hygienic sealing

-

Robust AISI 630 rotor and stator handle viscosities above 5,000 cP

-

Sanitary connections: DIN 11851, Clamp BS4285 or DIN 32676.

Options:

-

Integrated cooling circuit with flow switch and solenoid valves

-

Pusher pump for high‑viscosity fluids.

-

CIP or water‑flush ports for easy cleaning.

Applications -

Food and beverage milling, cosmetic creams, emulsions and pharmaceutical suspensions.

-

Suitable wherever precise particle size and high throughput are required.

Contact us to specify an inline colloid mill for your process.